Planning

If you’re wondering how much does it cost to build a storage facility, the real answer is: it depends on your site, scope, and local code.

Industry cost guides often show wide construction ranges (for example, $25–$110 per square foot, excluding the cost to buy the land itself). Use this page to turn that range into a budget you can stand behind.

For early budgeting, separate costs into a few clear buckets:

Site Preparation

Site prep cost for a storage facility is one of the biggest budget swing factors. Grading, drainage, and utility runs can change totals fast, even when the building footprint stays the same.

Plan for clearing, stormwater, drives, and access from the start. Permits, inspections, and any required off-site improvements are also location-dependent, so build time into your schedule for reviews and revisions.

Design

Design is where cost meets leasing. Door count, unit mix, and traffic flow affect how the facility operates, how fast tenants can move in, and how much labor goes into the build.

Keep finishes practical. Storage is high-use. Durable doors, clean trim details, and solid drainage handling reduce ongoing maintenance and improve the customer experience.

Cost Analysis

You may be looking for hard numbers, but treat these as planning guardrails as every project is unique. Many estimates place basic construction-only costs for simpler self-storage builds in the broad $25–$75 per square foot range. However, this range grows even wider once site work, upgraded systems, or climate control are included.

Use these “reality checks” when you compare potential numbers:

Site and permitting items can add tens of thousands depending on conditions and jurisdiction requirements. If you need a tighter budget, lock your facility model and ask for a scope breakdown so you know what’s included and what’s not.

Construction

Construction costs include labor, materials, and equipment. Foundation approach, wall height, roof/wall system choices, and door/hardware selections all affect both price and your timeline.

If you’re using a steel building kit, confirm what the “kit” includes and what it doesn’t (site work, slab, MEP, and installation may not be included). A clear scope of work prevents surprise change orders and makes bids easier to compare.

Cost Factors

Several factors influence storage building costs, including the choice of materials, labor costs, and location. High-quality materials may have a higher upfront cost but can save money on maintenance and repairs in the long run.

Labor costs can vary based on the complexity of the project and the region where you are building. Additionally, the location of your storage facility can impact costs related to permits, inspections, and local regulations. Understanding these factors helps in making informed decisions for your investment during the construction process.

Size and Space

The overall size of the project drives total spend, but it can also improve efficiency. Some costs don’t scale linearly, so larger projects may seem to have a “better” cost per square foot at first—until site constraints or infrastructure limits kick in.

This is your first time developing a budget to build a self-storage facility, consider phasing your project. Build a first phase that matches the market demand for your area, then expand as occupancy grows. Just make sure the original layout has plenty of room to support future rows of units, drive aisles, and utilities.

Climate Control

Climate-controlled storage can attract tenants who want temperature and humidity protection. It can also increase the build scope because you’re adding building envelope details and mechanical planning.

Focus on the basics: insulation approach, ventilation, and condensation control. In humid climates like the Southeast United States, these details matter for long-term performance. Before you commit, research the local demand for climate-controlled storage units and see what your competitors are offering so your investment matches what your market will pay for. Here is more information on how to build climate-controlled units.

Location

Urban builds often come with higher land prices, higher labor costs, and tighter sites. Review timelines can be longer, and utility coordination may be more complex.

Rural sites may offer lower land cost, but you may spend more on infrastructure if utilities are farther away. The right location depends on competition, visibility, access, and where renters live and work.

Budgeting

Effective budgeting is crucial for building a storage unit facility. Start by estimating all storage facility costs, including development, construction, and ongoing operational expenses. A detailed budget helps manage unexpected costs and keeps the project on track.

Incorporating a contingency fund in your budget can provide a financial buffer for unforeseen expenses. Careful planning and realistic budgeting will ensure your storage unit building project is financially viable and successful.

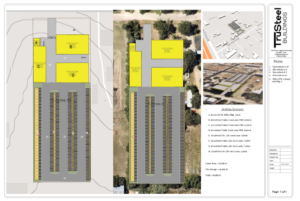

From site plans to actual buildings, we have you covered.

Professional Help

If you want fewer surprises, work with a partner who prices to your location and understands permitting. TruSteel supports storage projects with 100% American-made steel building kits and an IAS-accredited manufacturing and vendor supply chain.

Where required, we can provide county-specific stamped building and foundation plans. With the right inputs, we can typically deliver a quote plus a preliminary sketch in 24–72 hours. Panels and columns are backed by a 30-year manufacturer’s warranty, and you get a single point of contact from quote through delivery.

For a more accurate quote, have the following information ready:

If you’re comparing mini storage building kits or self storage building kits, start with a scope review and a location-based quote. Get a free quote to see what your project looks like on paper before you commit.

Selecting the ideal roof pitch for your metal building kit is an important decision that hinges on a few key considerations. If your area is prone to heavy snowfall, opting for a steeper roof pitch can help snow management. However, it’s important to balance this with the cost implications, as a higher pitch can increase the overall price of your building.

A 0.25:12 roof pitch strikes that perfect balance for most customers. This pitch is not only cost-effective but is as efficient in bearing snow weight as a 6:12 pitch. While a higher pitch can aid in shedding snow more quickly, remember that it comes with a higher cost. Our goal is to help you make an informed choice that aligns with both your environmental needs and budget, ensuring your building is both functional and financially feasible.

to Learn More or Get a Free Quote